R & D strength

R & D strength

In order to improve the company's intelligence level, the company has transformed and upgraded to create a green smart factory with adaptability and resource efficiency, and ultimately move towards Industry 4.0. The Lithium Battery Project introduces core technologies and equipment for intelligent manufacturing such as positive and negative electrode production, assembly, testing, warehousing/transportation and logistics of lithium-ion power batteries. Building intelligent processing centers and production lines, intelligent production control centers, intelligent production execution process control systems, intelligent warehousing/transportation and logistics systems, and cloud service platforms.

Craftsmanship:High vacuum high temperature baking moisture removal technology high temperature fixture into intelligent contact baking process

Safety testing:Through a number of extreme safety tests, no fear of risk safety escort every trip.

Safety detection

Mechanical safety

Vibration test, extrusion test, mechanical impact test, flip test, simulated crash test, drop test

Electrical safety

Insulation withstand voltage, short circuit protection, over temperature protection, overrush and discharge test, electromagnetic compatibility test

Safety Design

Structural safety, electrical safety, thermal safety, functional safety, abuse safety

Functional Design

Seawater immersion test, external fire test, temperature shock test, high altitude test, high temperature damp heat test, salt spray test

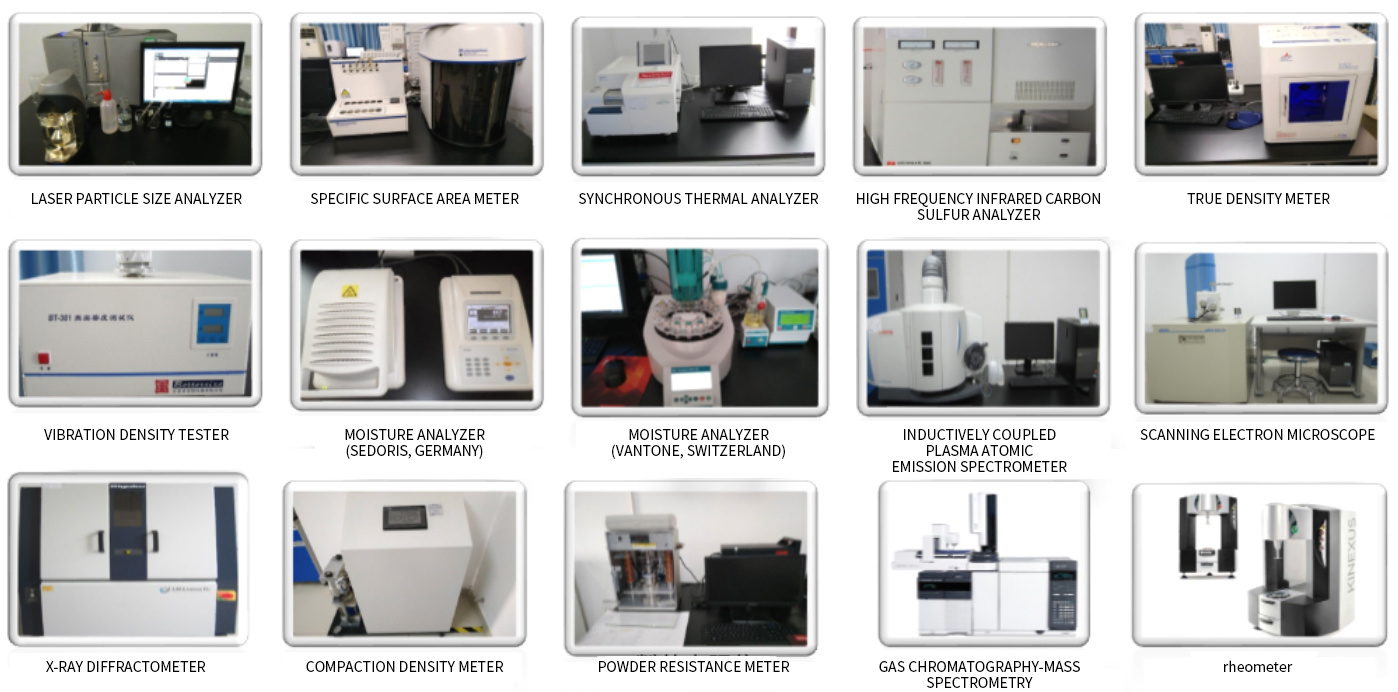

R & D Equipment